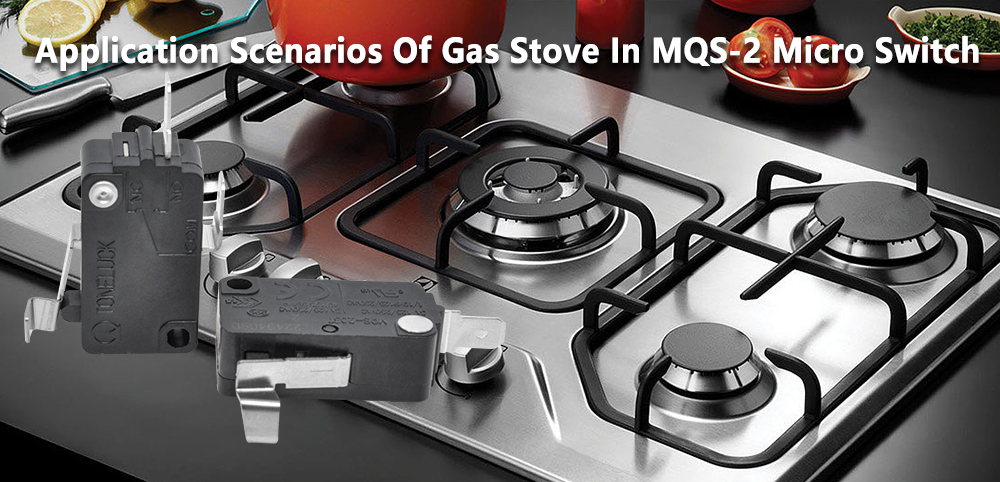

The MQS-2 microswitch is a common electrical component typically used in mechanical or electronic equipment to detect the position of objects, trigger actions, or switch circuits. In gas stoves, MQS-2 micro switches can be used in a variety of application scenarios.

Gas furnace valves are often integrated with the ignition system. At startup, the valve needs to open to allow gas to flow in, and the ignition system then kicks in to ignite the gas. When shutting down, the valve needs to close to stop the gas supply. This ensures that the stove only releases gas when needed. Modern gas stoves often feature digital control systems that automatically adjust the position of the valve for more precise temperature control. These systems may adjust valves based on preset temperature settings or sensor feedback. The control of gas stove valves involves ensuring the appropriate supply of gas in the furnace cavity to meet user needs and ensure the safe operation of the stove. This involves mechanical and electronic systems working together to achieve precise and reliable valve control.

The furnace door is another important mechanical component. A microswitch can be placed near the furnace door to detect whether the furnace door is open or closed. If the oven door is not closed correctly, the micro switch can trigger the safety system to take appropriate measures, such as stopping the gas supply or sounding an alarm.

Flame sensors are commonly used to detect flames in furnace chambers. Micro switches can be used to ensure that the flame sensor is in the proper position to accurately detect combustion conditions. There may be some temperature control devices in your gas stove, such as an adjustable thermal element. Microswitches can be used to detect the position of these controls to ensure they are correctly sensing temperature and triggering appropriate control operations.

-

Ignition system control

The MQS-2 microswitch can be used to detect some critical positions in the ignition system, such as the position of the ignition electrode. When the stove needs to start ignition, the micro switch can trigger the operation of the ignition system.

-

Gas stove valve control

In some gas furnaces, the MQS-2 micro switch can be installed on the valve or valve control mechanism to detect the open or closed status of the valve. This helps ensure that the valve opens or closes at the appropriate time to control the flow of gas. Valve control of a gas furnace is a critical aspect that involves controlling the flow of gas, ensuring that it is introduced at the right time and shut off when required. The main goal of valve control is to ensure safe operation, high efficiency, and user-friendliness of the stove.

-

Temperature control

The MQS-2 microswitch can also be used in conjunction with a temperature probe or sensor to monitor the temperature within the oven cavity. In some cases, microswitches may be used to trigger the thermal control system when a specific temperature is reached to ensure that the oven cavity remains within a safe and appropriate temperature range.

-

Gas stove safety system

The MQS-2 microswitch can be integrated into a gas furnace’s safety system to detect abnormal conditions. For example, when the furnace door is not closed properly, the micro switch can trigger the safety system to stop the gas supply to prevent gas leakage. The safety system of a gas stove is to ensure that the equipment follows safety standards during use, prevents accidents, and reduces potential dangers.

Security systems may include gas leak detectors to detect if there is a gas leak. If a leak is detected, the system can trigger an emergency shutdown of the gas valve and simultaneously sound an alarm to alert users and ensure safety. Users can usually manually trigger the safety system via an emergency stop button, immediately cutting off the gas supply and stopping the operation of the stove. This is a user-controllable security measure.

When abnormal conditions are detected, the safety system can automatically close the gas valve to cut off the gas supply. These security systems are designed to provide multiple layers of security to protect users from potential dangers. When using a gas stove, users should regularly check the effectiveness of the safety system and ensure that the system is working properly.

-

Position detection of gas furnace mechanical parts

There may be some mechanical parts inside your gas stove, and micro switches can be used to detect their position, ensuring they are in the proper position to start or stop specific functions. The gas valve in a gas furnace is a critical mechanical component. Micro switches can be installed on the valve mechanism to detect whether the valve is open or closed. This helps ensure that the gas valve opens correctly when needed and closes when not needed to prevent gas leaks.

The furnace door is another important mechanical component. A microswitch can be placed near the furnace door to detect whether the furnace door is open or closed. If the oven door is not closed correctly, the micro switch can trigger the safety system to take appropriate measures, such as stopping the gas supply or sounding an alarm.

Flame sensors are commonly used to detect flames in furnace chambers. Micro switches can be used to ensure that the flame sensor is in the proper position to accurately detect combustion conditions. There may be some temperature control devices in your gas stove, such as an adjustable thermal element. Microswitches can be used to detect the position of these controls to ensure they are correctly sensing temperature and triggering appropriate control operations.

How does a micro switch improve the function of a gas stove?

The application of micro switches in gas stoves can improve the functionality of the equipment, and increase safety and user experience. Micro switches can be used to detect the status of the furnace door to ensure that it closes at the appropriate time. If the furnace door is not closed properly, the micro switch may trigger the safety system to stop the gas supply, prevent gas leakage, and ensure user safety.

Micro switches can be integrated with gas valves to detect the open or closed status of the valve. This helps ensure that the gas valve opens correctly when needed and closes when not needed to prevent gas leaks. Micro switches can be used in conjunction with temperature sensors to monitor the temperature in the oven cavity. When the set temperature threshold is reached, the micro switch can trigger the control system to take corresponding measures, such as adjusting the flame size or stopping heating, to ensure that the temperature is within a safe range.

In ignition systems, microswitches can be used to detect the position of the ignition electrode. This helps ensure that the ignition system is working as intended to ignite the gas reliably. Micro switches can be used as part of a gas furnace safety system to detect abnormal conditions and trigger corresponding safety measures, such as stopping the gas supply or sounding an alarm.

Through the rational use of micro switches, gas furnaces can operate more intelligently, safely, and efficiently. This helps improve the user experience while ensuring the reliability and stability of the device during use. Designers and manufacturers can take advantage of the flexibility of microswitches to optimize gas stove performance based on specific functional needs.

Working principle of gas stove MQS-2 micro switch

The MQS-2 micro switch is a mechanical switch whose working principle is based on its internal tiny contacts and spring mechanism. Micro MQS-2 movable switches usually consist of a movable spring arm and one or more contacts. When the spring arm is acted upon by an external force, it bends, causing the circuit between the contacts to open or close.

MQS-2 micro switch has two basic states: normally closed and normally open. In the normally closed state, when no external force acts, the contacts are closed, and the circuit is open; while in the normally open state, when no external force acts, the contacts are open, and the circuit is broken.

The spring arms of MQS-2 microswitches tend to be very sensitive. When an external force acts on a lever or other mechanical component on the spring arm, the spring arm bends, changing the state of the contact. In gas furnaces, MQS-2 micro switches can be installed near furnace doors, valves, ignition systems, or other critical components. When a specific event or status change occurs, such as the furnace door closing, the valve opening or closing, the ignition system needing to be started, etc., the micro switch will be triggered accordingly.

The contacts of the MQS-2 microswitch can be used to control circuits, such as starting or stopping the electric drive of gas valves, ignition system circuits, etc. Changes in the status of the contacts will cause changes in the working status of the corresponding electrical equipment.

Through its sensitive spring mechanism and contacts, the gas stove MQS-2 micro switch can detect specific mechanical movements or status changes in the stove, thereby triggering relevant control actions to ensure the normal operation and safety of the stove. The use of MQS-2 micro switches increases the intelligence and programmability of the stove system.